Netflix Sound Stages

Location: Alburquerque, New Mexico

Date of Completion: 2024

FlowCon International Products Used: FlowCon E-JUST Valves

Griswold Controls Products Used: Griswold Controls Quickset Valves

Description:

Vibrant and film-friendly, Albuquerque bears many names: “The heart of the American Southwest,” and “Hollywood away from Hollywood,” to name a few. In 2018, Netflix decided to establish a major production hub in Albuquerque, New Mexico. This plan to establish a major production hub coincided with the acquisition of Albuquerque Studios which sat on a 28-acre site, eight sound stages, production offices, and a backlot. This commitment included a substantial $1 billion investment in production spending, promising the creation of up to 1,000 production jobs annually in the state, 300 more acres, and 10 new sound stages. Interestingly, this is where “Better Call Saul” and “Hell or High Water” completed production.

Fast forward to today, Netflix sits atop the world of streaming with its worldwide audience numbered at 231 million subscribers. This project is focused on the additional 10 sound stages. Not only will these aid filmmakers in creating and capturing sound, but producers and other audiovisual projects stand to benefit from soundstages.

In the pursuit of expanding Netflix’s U.S. production capacity and capabilities, the Netflix Sound Stages in Albuquerque, New Mexico, emerged as a visionary endeavor. This initiative aimed not only to foster local film and television industry growth but also to deliver unparalleled sound and visual effects for a diverse range of Netflix original content, including beloved titles like Stranger Things, El Camino: A Breaking Bad Movie, and The Night Shift.

Project Description:

This visionary initiative is poised to redefine the landscape of film and television production in Albuquerque. More than just a collection of sound stages, it represents a significant leap forward in Netflix’s quest to expand its U.S. production capabilities. The overarching goal is clear: to craft an environment conducive to creativity, innovation, and the production of high-quality content that captivates global audiences.

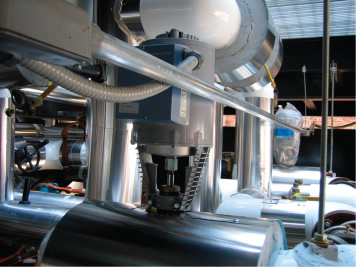

With great vision comes unique challenges. The design and installation of a sophisticated HVAC system emerged as a pivotal component of the Netflix Sound Stages project. The objective was clear—to create an environment that not only meets the diverse heating and cooling demands of the sound stages but also adapts seamlessly to the distinct seasons and weather conditions of New Mexico.

Some of these unique challenges require flexible HVAC system capable of meeting the varying demands of the sound stages, New Mexico’s diverse seasons, and fluctuating weather conditions. These solutions need to be robust and reliable. Balancing the flow and pressure of chilled and hot water systems is a meticulous task, all while minimizing noise and vibration that could disrupt the high-quality sound recording and editing essential to productions.

Enter Griswold Controls and FlowCon International, distinguished manufacturers of flow control valves and solutions, providing our expertise and products. FlowCon’s E-JUST valves were instrumental for automatic balancing and flow adjustment in the field, incorporating insert-based and externally adjustable capabilities. The E-JUST valves are designed to maintain constant flow in a HVAC system regardless of pressure fluctuations. These valves have a flow limiting cartridge that dynamically absorbs pressure changes and controls the flow to within +/- 5% of the designed flow.

Griswold Controls’ QuickSet valves played a crucial role in manual balancing and flow measurement, equipped with features like brass venturi inserts for precision flow measurement and graduated memory stops for accurate flow settings.

The collaboration delivered tangible benefits for the Netflix Sound Stages, including improved temperature and humidity control, reduced energy consumption, enhanced flexibility for field adjustments, minimized noise and vibration, and simplified installation and maintenance processes. The partnership between Griswold Controls and FlowCon not only addressed the challenges but elevated the overall efficiency and functionality of the HVAC system, ensuring optimal conditions for the production of Netflix’s high-profile content.

Photo from Seattle Times

About Massey Johnson, Associates

Massey Johnson, Associates was founded in 1974 when Billy Massey merged his company with Herlin Equipment Company. Today, Massey Johnson Associates is a commercial plumbing specification and engineered products representative. They have five full time employees in Albuquerque, ten in El Paso, and two in Colorado. Massey Johnson is well rounded with product offerings which include commercial plumbing, pumps, boilers, and other engineered products.

Have a question about this or another Featured Project? Fill out the form below and someone from Griswold Controls will get back to you shortly.