Casinos take hospitality seriously! A good casino’s first priority is to take care of their guest and make them comfortable. Griswold Controls has been helping casinos with guest comfort for decades.

Hydronic HVAC Systems

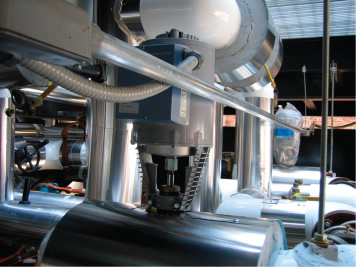

Since 1960 Griswold Controls has made automatic flow limiting (automatic balancing) valves for the hydronic HVAC industry. They have valves installed in casinos all over the world. An automatic flow

limiting valve maintains a constant flow in spite of pressure changes in the system, so the heating or cooling coil in each zone has the flow it needs at all times.

limiting valve maintains a constant flow in spite of pressure changes in the system, so the heating or cooling coil in each zone has the flow it needs at all times.

In comparison, when a system is unbalanced you have some equipment in the building that has excessive flows due to high-pressure differentials; and some equipment that has inadequate flows due to lower pressure differentials. High flows can lead to excessive heating/cooling, high-velocity noise and erosion, wasted pump energy, and dehumidification problems. Low flows can lead to inadequate heating/cooling and short-circuiting of equipment. Typically an unbalanced system has the higher flows near the pumps and the lower flows are in the index circuit, the equipment farthest from the pump. These low flow and high flow issues are a disaster for a casino manager. They can lead to excessive guest complaints which can impact occupancy. The natural reaction to complaints about inadequate heating or cooling is to increase pump speed which leads to increases in pump energy and wastes money.

Domestic Hot Water Recirc System

Many Casinos also have hotels to add to their guest experience. Cold showers and lack of hot water are also a hotel manager’s nightmare! Unbalanced systems also happen in domestic hot water recirc and lead to loud complaints from guests and impact occupancy rates.

The same flow issues that exist in an unbalanced HVAC system also exist in an unbalanced domestic hot water recirc. systems. But now you have the added issue of users having inadequate hot water for their shower or faucet. That can lead to much more angry complaints! So balancing a domestic hot water recirc. system is as important as balancing an HVAC system.

Often these systems are balanced with ball valves or manual balance valves, both requiring balancing labor and in the end, neither maintain balance when the system has pressure changes. Unlike HVAC systems, these are open systems and as people open and close faucets and run washers it causes even more pressure changes than an HVAC system  experiences which can cause even more flow changes. Another factor with an open system is water will take the path of least resistance. So if a faucet is open close to the pump in an unbalanced system the faucet farthest from the pump will have less hot water available to it.

experiences which can cause even more flow changes. Another factor with an open system is water will take the path of least resistance. So if a faucet is open close to the pump in an unbalanced system the faucet farthest from the pump will have less hot water available to it.

The same flow limiting cartridge used in our HVAC valves can be installed in a lead-free valve and used to control the flow in domestic hot water systems. The burden of balancing is shifted from the contractor to the valve itself; as it maintains flow, regardless of pressure changes, through the life of the valve.

Impacts on Guest Experience

Recently a building manager was interviewed on impact in their system of removing Griswold Controls automatic flow limiting cartridges for cleaning. They said they had complaints about inadequate hot water from the day the parts were removed for cleaning. Once they were replaced the complaints stopped. So adding automatic valves can guarantee the hot water is distributed to each unit; and remains balanced regardless of system pressure changes.

Typical domestic hot water recirc systems use flow limiting valves set at 0.55 gpm. While 0.55 gpm is adequate for a faucet or shower, the flow can be different for larger zones. Since the valve is pre-set for the flow no human balancing is required. This is less flow than is typically specified for a manual system. They have to pump more flow to make sure that there is enough hot water at every location when the system is unbalanced due to pressure changes. Designing for less flow means smaller pumps which saves money on initial install costs.

Don’t gamble with your guest’s comfort! Use Griswold Controls Balancing Valves on your HVAC system; and your domestic hot water recirc system to guarantee guest comfort and increase the house advantage!

Do you have a question on this Application Tip or any of the Griswold Controls products? Fill out the form below and someone from Griswold Controls will get back to you shortly.

Questions about this application? Contact info@GriswoldControls.com, call 949.559.6000 or fill out the contact form on this page.

To view more application tips click here!

Read about Griswold Controls’ work in Entertainment below:

Netflix Sound Stages

Peppermill Resort Tower

Aquarium of the Pacific – Otter Surrogacy

Video Credit: YouTube

Las Vegas’ Wynn Hotel & Casino

Wynn Las Vegas Resort – Las Vegas

Utilization of Griswold Controls coil piping packages to save a significant amount of install time for the new Wynn Las Vegas Resort.

Project Overview

The most recent – and stunning – addition to the southern Nevada skyline is the new Wynn Las Vegas Resort. Built at a cost of $2.7 billion dollars and opened in April 2005, the 50-story bronze tower contains 2,700 luxury hotel rooms with floor-to-ceiling windows, 22 restaurants, the 2,000 seat “Aqua Theater-in-the-Round,” and the “Promenade” with luxury boutique shopping. Built on the site of the former Desert Inn, it also includes an 18-hole golf course. Whereas most high-end hotels have car rental desks, Wynn Las Vegas houses a Ferrari-Maserati car dealership inside the resort. The front entrance and three-acre Lake of Dreams are shielded from the street by a 140-foot tall mountain with 60-foot tall pine trees.

Steve Wynn, who had previously built the Mirage (1989), Treasure Island (1993) and Bellagio (1998) hotels, conceived and developed Wynn Las Vegas. Several years ago he sold those three properties to MGM Grand in order to develop Wynn Las Vegas. This resort-casino clearly establishes a new threshold for local, high-end properties. JBA Consulting Engineers, Las Vegas, is the mechanical engineering firm responsible for the project. Bid and mechanical construction activity was divided into seven distinct areas, and the specification allowed for either automatic or manual flow controls. Southland Industries, Las Vegas, handled area one and the central plant, and Hansen Mechanical of Las Vegas was awarded responsibility for areas two through seven, which covered the tower.

Engineered Equipment & Systems Co., the Griswold rep for southern Nevada, successfully convinced Southland Industries and Hansen Mechanical to utilize Griswold coil piping packages. Unimizers® were installed on a majority of the fan coils, VAV boxes, heating coils and heat pumps in the hotel rooms, showrooms, the Aqua Theater and the villas.

According to Matt Miceli, the Engineered Equipment & Systems Co. sales engineer responsible for the project, the Unimizer packages significantly reduced Hansen’s ATC coordination costs. Matt said, “Hansen has been a Griswold Controls customer for some time. They especially like Griswold’s coil hookup packages and the way we shrink-wrap them. No other vendor provides this packaging concept. This project also offered them the opportunity to add the Unimizer® to the packages, which greatly simplified the coordination with the ATC contractor. The project time frame was extremely aggressive and the Unimizer® packages saved the contractor a significant amount of install time.” James Gomel, Hansen Mechanical project manager, stated, “The Griswold coil-piping packages allow for installation consistency to the systems along with a valuable savings in labor cost. In addition, incorporating the Unimizer® with the package allows for a complete installation of the coil-piping package, thus eliminating the need for additional labor required to install the controller in the field."

In total, over 2,000 Griswold Controls piping packages are installed on the project along with over 20 air handler packages in area one. In addition to the flow controls and coil piping packages, Engineered Equipment & Systems Co. sold in excess of $100,000 worth of Griswold Filtration separators and separator package filtration systems for the numerous cooling towers on the project.

Have a question about this or another Griswold Controls Case Study?

Fill out the form below and someone from Griswold Controls will get back to you shortly.

Los Angeles Music Center’s Disney Concert Hall

Los Angeles Music Center’s Disney Concert Hall

By providing piping packages to help offset installation costs and to take advantage of their space–saving features, Griswold Controls provided a cost-effective solution for the hot and chilled water fan coils and air handlers.

Project Overview

An Iconic Venue for an Iconic Solution

The Concert Hall was designed by Frank Gehry, an internationally recognized architect whose many credits include the Guggenheim Museum in Bilbao, Spain and the American Center in Paris. The ceiling of the building features wavy, steel forms which are designed to appear like a ship with billowing sails at full mast.

Groundbreaking commenced on the project in late 1999, and the Concert Hall was finally dedicated in 2003 at an ultimate cost of $274 million. This ‘monument to music’ became the key to the resurgence of downtown Los Angeles and a beacon for the extensive commercial and condominium housing development which has followed.

The Griswold Controls Solution

Griswold Controls’ Los Angeles rep, Mahendra Mistry, owner of JD Sales Co., worked with the project’s mechanical engineering firm, Levine/Seegel Assoc. of Santa Monica, CA, to obtain favorable specifications for Griswold Controls automatic FCVs, calling out individual FCVs for various terminal units per the piping arrangement shown on the drawings.

ACCO Engineered Systems of Glendale, CA, the principal mechanical contractor, was intent on using piping packages to help offset installation costs as well as take advantage of their space–saving features without compromising the piping arrangement shown on the drawings. Mahendra worked closely with Frank Falcone, Bill Traub and Mike Masterman of ACCO to sell nearly 200 Isolator™ Y coil piping packages for installation on the VAV boxes and another 60+ automatic flow controls on the hot and chilled water fan coils and air handlers.

- ~200 Isolator™ Y Coil Piping Packages Installed on VAV boxes throughout the facility.

- 60+ Automatic Flow Controls Installed on hot and chilled water fan coils and air handlers.

- Quickset® Manual Balance Valves Installed on pump discharge risers in low-headspace basement conditions.

Overcoming a Unique Installation Challenge

Another challenge presented itself regarding the flow measuring devices specified on the pumps. The pumps were installed in the basement with limited headspace below the ceiling. None of the specified devices could be accommodated because of their requirement for normal upstream and downstream pipe diameters on the vertical discharge risers.

Although not specified for these manual devices, Mahendra worked closely with ACCO through 4 submittals to gain approval of Griswold Controls’ Quickset® manual balance valves, utilizing their disturbed flow technology as the only alternative that would fit in the low headspace and still provide the specified accuracy.

Griswold Controls and JD Sales are very proud of their involvement in this world–class project.

Questions about this application? Contact info@GriswoldControls.com or 949.559.6000

Have a question about this or another Griswold Controls Case Study?

Fill out the form below and someone from Griswold Controls will get back to you shortly.

CBS Studios, Manhattan, New York

CBS Studios – New York City

Ensuring TV anchors keep their cool using MVP valves and Isolator™ Rs Uni-Flanges on chilled water system.

Project Overview

The Challenge

CBS Studios faced a daunting challenge controlling cooling capacity in their Manhattan sound and TV studios. Manual balancers struggled due to multiple pumps and partial VFD control, making temperature control unreliable. Griswold Controls was contracted to provide a solution.

Kristen Ortlinghaus of Griswold Controls and MDM Consulting Engineers collaborated to select the correct valves for the project. MVP™ pressure independent valves, Isolator™ Rs, and Uni-Flanges were chosen. The installation schedule was aggressive: first shipment in four weeks, complete installation in seven weeks.

After completion, CBS was extremely satisfied, planning to use additional MVP valves and convert all manual-balanced coils to Griswold Controls products in the future.

Valve Products

Isolator™ & “K” Automatic Flow Control Valves

Isolator and “K” automatic flow control valves are available with a wide range of flows and PSID, and are ideal for tight spaces. These valves offer easily accessible flow control cartridges combined with isolation ball valves, allowing exchange of the flow control cartridge without breaking pipe connections if system flow requirements change. They also simplify maintenance of coils and temperature controls. Perfect for terminal boxes, VAV boxes, fan coil units, heat pump installations, and baseboards/in-cabinet applications.

QuickSet® Manual Balance Valves

QuickSet manual balance valves make proportional or static balancing simple and fast. Available in standard configurations or with accessory ports, QuickSet valves feature patented Optimizer® parabolic flow inserts for minimal handle movements and smooth flow changes. Full range handle position control ensures precise flow is achieved immediately. Ideal for casinos, hotels, VAV boxes, fan coil units, and heat pump installations.

Unimizer® Actuated Control Valves

Unimizer 2- and 3-way actuated control valves provide precise temperature control wherever actuated ball or globe valves are needed. They feature high close-off pressure, multiple Cvs for exact pressure drop matching, and equal percentage flow via the patented Optimizer® insert. Ideal for hotels, schools, terminal units, VAV boxes, air handling units, fan coil units, heat pump installations, equipment rooms, and pipelines.

Automizer® Combination Control Valves

Automizer all-in-one valves combine an actuated temperature control valve with a stainless steel automatic flow limiting cartridge. They integrate the entire return side of the coil in one unit: flow limiting valve, actuated 2-way control valve, and manual isolation ball valve. Patented Optimizer® ensures equal percentage flow characteristics. Ideal for schools, office buildings, VAV boxes, fan coil units, heat pump installations, and terminal boxes.

PIC-V® Pressure Independent Control Valves

PIC-V pressure independent control valves maintain accurate flow regardless of pressure fluctuations, providing stable balancing at all points up to maximum flow rate, eliminating hot and cold spots. They combine balancing and control valve functionality into one compact housing. Perfect for office buildings, prisons, hospitals, laboratories, computer centers, and high-tech manufacturing.

Questions about this application? Contact info@GriswoldControls.com or 949.559.6000

Have a question about this or another Griswold Controls Case Study?

Fill out the form below and someone from Griswold Controls will get back to you shortly.