Monteleone Hotel Update, New Orleans

Griswold Controls helps to preserve a New Orleans landmark via a retrofit of the HVAC system using control valves & coil piping packages.

Application: Hotel

Griswold Controls Solution: Automizer® combination control valves & coil piping packages

Engineer/Consultant: Wink Engineering

Hotel Chief Facilities Engineer: A.J. Mattern

Rep Group: Schully Strawn & Assoc. Gary Lewis

Completion Date: 2002 phase one | 2004 phase two

Located in the heart of the French Quarter, the Hotel Monteleone is a beautiful, 15 story BeauxArts-style historic landmark that over the years has undergone expansive restoration, transforming it back to its original and legendary stature as New Orleans’ Grand Dame Hotel. The property features 600 luxurious rooms that contain all the modern amenities guests expect, while preserving its traditional atmosphere. In 2002, given its age, the hotel’s HVAC system was badly in need of a retrofit. Wink Engineering, the engineering firm handling the HVAC retrofit, working with the Griswold Controls sales representative Gary Lewis of Schully Strawn & Associates, agreed the best solution was installing Automizer® combination control valve coil piping packages on the four-pipe fan coils. The purchase of the valves and packages was hotel direct, so Gary worked closely with the hotel’s chief facilities engineer, A.J. Mattern, to ensure Automizer packages were selected and purchased. Mattern recognized the benefits of buying Griswold Controls Automizer packages right

away, which include:

- A single source for all coil components

- A multi-function valve offering the performance of an actuated control valve and a flow limiting valve in one compact package

- A small footprint

- Equal percent control for the coils

- Hassle free product distribution at the job site

During the first phase of the project, the Monteleone Hotel renovated their guest rooms with 288 Automizer CPP2A packages on the horizontal units, and a number of 3-way Unimizer® actuated control valves on the vertical units. In 2004, the hotel was ready to being the second During the first phase of the project, the Monteleone Hotel renovated their guest rooms with 288 Automizer CPP2A packages on the horizontal units, and a number of 3-way Unimizer® actuated control valves on the vertical units. In 2004, the hotel was ready to being the second phase of this renovation, and ordered 112 more Automizer coil piping packages. The purchase of the Griswold Controls valves for the second phase was automatic. As Mattern describes it, “I told Gary to get the Griswold Control valves on order and let my purchasing department know how much the bill would be.”

Because the Automizer features automatic flow control, the retrofit can be accomplished a few rooms at-a-time without affecting the rest of the hotel’s circuits, making them the ideal product for hotel renovation. If a similar situation existed in a manual balance application, the entire system would have to be manually rebalanced. By installing the Automizer, the hotel loses only a minimum number of rooms for the least amount of time, substantially decreasing the potential for lost revenue.

Gary Lewis summed the job up this way, “It’s nice when you are selling a quality product like Griswold Controls. You put your time and effort into getting that first order, and then getting the next order just takes a few minutes on the phone.” When asked about the valves’ performance Mattern replied, “They work great! I’m very satisfied and look forward to buying Griswold Controls for every new FCU in the hotel as we continue to renovate additional rooms.”

Questions about this application? Contact info@GriswoldControls.com or 949.559.6000

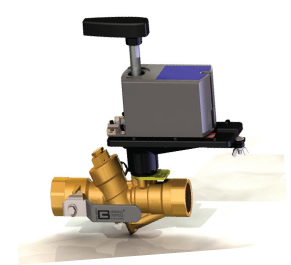

Automizer® combination control valves

Automizer® Next Generation combination control valves feature Griswold Controls’ patent pending field repairable stem design, providing resistance to today’s chemical treatments and to temperature fluctuations following evening system shutdown. In addition, they allow for field servicing without having to remove the valve from the system.

Automizer all-in-one valves combine an actuated temperature control valve with our stainless steel automatic flow limiting cartridge. The Automizer contains the entire return side of the coil in one valve: a flow

limiting valve, an actuated 2-way control valve, and a manual isolation ball valve. In addition, these valves feature the patented Optimizer for equal percentage flow characteristics. Automizer valves are ideal for schools, office buildings, VAV boxes, fan coil units, heat pump installations, and terminal boxes.

| Features | Benefits |

|---|---|

| Automizer Cv ratings match those of globe valves | Matches the flow range most systems are designed for, and offers performance of a globe valve at a ball valve price |

| Automizer valves feature the patented Optimizer® parabolic flow inserts | Delivers equal percent control, which mirrors the coils' heat transfer, and also provides for 30-50% more rotation response than other ball valves |

| Automizer valves have a stainless steel automatic flow limiting cartridge | Eliminates overflow, where total flow exceeds the flow required for the system, and underflow problems |

| Automizer valves have multi-actuator compatibility | Allows use in many applications because the same actuator is not the right choice for every job |

| Automizer valves contain next generation triple seals & field repairable stems | Provides resistance to today’s chemical treatments and to temperature fluctuations following evening system shutdown, and allows for field servicing without removing valve |

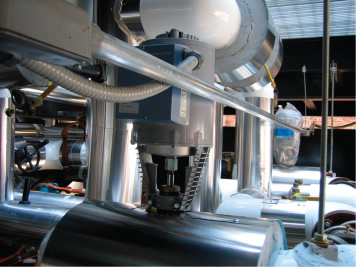

Coil Piping Packages & Hose Kits

Coil Piping Packages and Hose Kits are pre-plumbed solutions for specific piping needs, saving time, labor and money, while offering the added convenience of hassle-free product distribution at the job site Griswold Controls’ Coil Piping Package program includes over 900 standard packages. Engineers do not have to design or detail the various elements that are required at the supply and return end of each coil. They can just select one of Griswold Controls standard packages, which are available for both automatic and manual flow control applications. We also offer downsized components to the automatic temperature control as a standard package. Standard packages up to 2″ ship within 48 hours after the order is received direct to the job site, pre assembled and ready to install. If variations to the standard packages are necessary they can be readily accommodated, but they will affect the 48 hour ship time. In addition, options such as hoses and extension kits can be easily added, but similarly this will increase the lead time.

Standard Packages offer:

- Wide selection of pre assembled, easy to order configurations

- Easy ordering: order by specific part numbers

- Timely delivery

- Variety of options: downsized automatic temperature control, extra pressure / temperature ports, and the inclusion of Griswold Controls Automizer combination control valves or Unimizer actuated control valves

| Features | Benefits |

|---|---|

| CPPs & Hose Kits offer a wide selection of standard, preassembled configurations utilizing 15 years experience | Eliminates having to design or detail all elements needed at the supply and return end of each coil, saving time |

| CPPs & Hose Kits feature rapid shipment to the job site on standard packages up to 2” | Ensures product gets to the job site quickly and hassle-free, reducing labor and material costs |

| CPPs & Hose Kits are shrink wrapped and labeled with tag location | Provides for fast distribution with little handling by the contractor, saving time and money |

| CPPs & Hose Kits are available for both automatic or manual flow control | Offers compatibility with any system, thereby meeting all balancing needs |

| CPPs & Hose Kits come in custom packages that may include flow control valves, strainers, ball valves, unions, hoses, and other accessories, all chosen with the help of our engineering services | Allows all components to be purchased from one source, streamlining the ordering process and eliminating possible compatibility issues between components |

| CPPs & Hose Kits come with threaded or sweat connections; or flange, weld, or grooved end per the size | Provides a match for virtually any piping system |

Have a question about this or another Griswold Controls Case Study? Fill out the form below and someone from Griswold Controls will get back to you shortly.