Have you ever wished you could repair a leaking valve in the field without having to remove the valve from the system? Have you ever had problems with chemical treatments in HVAC systems destroying valve components? Have you had issues with hotter soldering practices mandated by legislation that eliminates the use of lead-based or other soft soldering materials damaging the stem o-ring and packing materials? If so, then Griswold

Controls’ Next Generation products are the answer you have been looking for.

Griswold Controls’ evolutionary line of products featuring our patent pending field repairable stem design address these problems and reflect a response to changes taking place in processes within the HVAC industry that can impact product performance. One issue contractors and end users have been dealing with for years is fixing leaks, a common occurrence with valves from major manufacturers to the smaller niche players. Griswold Controls is the only fullline major manufacturer with a solution for this problem.

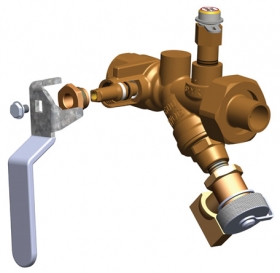

Repairable Actuated Valve Stem

Another issue facing contractors and end users is that the chemicals used to treat HVAC systems have changed. Treatment programs often include azole compounds that are not compatible with EPDM. In addition, many installers are required to use hotter materials and torches, and due to time constraints may not be able to close the ball on the valve and use a heat sink in accordance with written installation instructions when sweating in products. This practice can damage stem o-rings and packing material. Griswold Controls’ Next Generation products offer protection for their valves from both the use of chemicals in the systems and current soldering practices.

Next Generation products have addressed a need long unmet in the industry – offering an enhancement to product serviceability and at the same time answering the changing environment. Next Generation products provide:

- External stem accessibility allowing for field servicing without having to remove the valve from the system

- Safeguards against the chemical treatments used in many of today’s HVAC systems

- Protection from temperature fluctuations following an evening shutdown

- Resistance to legislated hotter soldering requirements

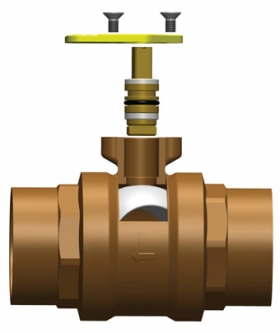

Repairable Isolation Ball Stem

With their resistance to various chemical compounds found in closed HVAC systems, their ability to address the hotter soldering requirements in many communities, and their field repairable stem design, our Next Generation products are true “preferred specification” products. No competitor has both the repairable dual seals (Griswold Controls has two Teflon® seals and one EPDM o-ring) combined with a grease reservoir (Griswold Controls has a grease reservoir that maintains lubrication on the EPDM seals to extend their life).

The product you need is only available from Griswold Controls, Field repairable stem with two Teflon seals and an EPDM o-ring. The Next Generation products are proving to be just what the market ordered.

Do you have a question on this Application Tip or any of the Griswold Controls products? Fill out the form below and someone from Griswold Controls will get back to you shortly.

Questions about this application? Contact info@GriswoldControls.com, call 949.559.6000 or fill out the contact form on this page.