David Braley Athletic Centre, McMaster University

Replacing the conventional control and balancing valves with Griswold Controls pressure independent control valves to reduce energy consumption.

Griswold Controls Has the Inside Track at McMaster University

The David Braley Athletic Centre, located on the campus of McMaster University, Hamilton, Ontario, is one of the largest fitness centres at any Canadian university. The athletic complex includes a double gymnasium, indoor 200-meter track, four squash courts, multipurpose studios for karate, yoga, dance and tai chi, and one of the only in-ground hydrotherapy pools in the country.

In August of 2006 David Braley, a Hamilton businessman, owner of the Canadian Football League’s B.C. Lions, and a former McMaster student-athlete, donated $5 million for the recreation centre. Commissioning was completed in the fall of 2006, and the centre’s first summer of operation was in 2007.

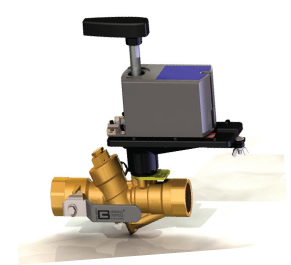

The building was originally specified with conventional control and balancing valves, but Kildonan Energy Products, the local Griswold Controls sales representative, working with University personnel and the construction/design team changed the air handler chilled water valves to Griswold Controls pressure independent control valves.

There are 11 valves, (10) PIC-V® and (1) MVP™ pressure independent control valves for the building, with total peak chilled water flow rate at about 300gpm. The coils were selected to provide a chilled water ΔT of 10º C (18º F). The building connects to the central plant’s chilled water supply and return lines, and contains variable speed chilled water booster pumps that only run if the mains’ differential cannot satisfy the building.

Griswold Controls (10) PIC-V® & (1) MVP™ pressure independent control valves guarantee ideal cooling system comfort performance and reduce energy consumption at David Braley Athletic Centre

Performance of the pressure independent control valves has been excellent. ΔT across the athletic centre has been as high as 17º C (31º F) with all systems meeting set point. As an example of the system’s effectiveness, one cool morning in September of ’07 the building was running with 24gpm of chilled water, less than 10% of the design flow. With the exceptional control provided by the Griswold Controls valves, chilled water flow requirements are very low and the booster pumps rarely, if ever, need to run.

McMaster University’s facility services personnel, under the supervision of Chief Operating Engineer Joe Emberson, are diligently dedicated to achieving ideal comfort performance combined with reduced energy consumption from the campus chilled water system. Griswold Controls’ pressure independent valves are proving to be an invaluable resource toward achieving those objectives.

Questions about this application? Contact info@GriswoldControls.com or 949.559.6000

Pressure Independent Control Valves

Griswold Controls’ MVP™ and PIC–V® are Pressure Independent Control Valves. Pressure independent valves dramatically reduce the energy costs, capital expenses, maintenance costs, performance issues, and capacity limitations associated with typical HVAC system pressure fluctuations. Pressure independent control valves are designed to replace the conventional 2-way control valve and balancing valve pair installed at heating and cooling coils in buildings. To obtain the most efficient and optimal results in a system, only the necessary amount, no more and no less, of chilled or heated water must be delivered to the heating and cooling coils at all times. This saves energy, increases available plant capacity, minimizes capital expenses necessary to acquire additional capacity, and simplifies system design and control.

Every year billions of dollars are wasted due to the weaknesses in HVAC heating and cooling systems. If heating and cooling systems do not consistently operate at their designed temperature differential, energy waste occurs and money is needlessly thrown away. This unnecessary expense can be eliminated by using Griswold Controls’ pressure independent valves.

When conventional 2-way valves are used to control the flow of water through coils various actions, such as adjusting a valve or changing the pump speed, affect pressure in the distribution system. These actions in turn affect the flow through a two-way valve even if the load does not change, and may in turn change the temperature in the space. The thermostat responds and the valve modulates to bring the flow back to what is required to meet the load. Until the flow is corrected, the coil operates at an off-design point and will over – or under – condition the space.

With a pressure independent valve design set point deviation will not happen. The valve responds only to a signal from a thermostat indicating the load has changed. A pressure independent valve will not feel the operation of other equipment on the system. By responding only to the change in load, the pressure independent valve is self–balancing, it delivers the proper amount of flow to meet the requirements of the load regardless of the state of other components in the system. By stabilizing heating and cooling coil flow in spite of pressure variations, more space can be heated and cooled with less equipment and less energy, and the entire HVAC system is always in a state of constant flow balance.

Griswold Controls’ MVP and PIC–V pressure independent control valves ensure that all HVAC systems achieve steady flow and high ΔT at all loads, guaranteeing stable temperature control and better heat transfer. This ultimately results in lower energy costs and lower flow requirements for proper heat transfer.

Have a question about this or another Griswold Controls Case Study? Fill out the form below and someone from Griswold Controls will get back to you shortly.

MVP™

MVP pressure independent control valves are designed to maintain the required flow rate in a system regardless of pressure fluctuations

| Features | Benefits |

|---|---|

| MVP Valves offer pressure independent control | Provides balancing at any point below and including the maximum flow rate, eliminating hot and cold spots in a building |

| MVP Valves reduce energy required to produce and distribute hot and chilled water | Increases chiller efficiency by 15-20% and increases Delta T across coils, thereby heating and cooling more space with less equipment and energy |

| MVP Valves experience no change in flow regardless of pressure fluctuations up or down stream of valve | Requires less work for the actuator and increases the actuator life |

| MVP Valves are pressure independent, multifunction modulating 2-way control valves | Combines differential pressure control with modulating control into one compact valve housing |

| MVP Valves reduce valve and actuator hunting by compensating for pressure changes in system | Increases occupant comfort, and extends both actuator and seat life |

| MVP Valves are low torque | Reduces actuator size needed, allowing for use of a less expensive actuator |

PIC-V®

PIC-V & SpaceSaver PIC-V pressure independent control valves combine a balancing valve & control valve into one, accurately maintaining flow control regardless of pressure fluctuations in the system

| Features | Benefits |

|---|---|

| PIC-V valves offer pressure independent control | Provides balancing at any point below and including the maximum flow rate, eliminating hot and cold spots in a building |

| PIC-V valves experience no change in flow regardless of pressure fluctuations up or down stream of valve | Can heat and cool more space with less equipment & energy, requiring less work for the actuator, thereby increasing the actuator's life |

| PIC-V valves control flow exactly | Eliminates all overflow or underflow at coils |

| PIC-V valves are low torque | Reduces actuator size needed, allowing for a less expensive actuator |

| PIC-V valves have a universal mounting plate | Offers compatibility with most manufacturer's actuators |

| PIC-V valves contain next generation triple seals & field repairable stems | Provide resistance to today's chemical treatments and to temperature fluctuations following evening system shutdown, and allows for field servicing without removing valve |